Tests completed

Tests completed

All in all, our testing activities have been a great success. Some petTracer test sets have lasted surprisingly long. It was possible for us to analyze and test all information transmissions and protocols as well as our server infrastructure. We obtained a very good idea of the cat owner and cat behavior in order to improve/verify our Use Cases accordingly (first steps, firmware updates etc.). We have received many valuable inputs from our testers and we can still implement most of them.

Safety buckle

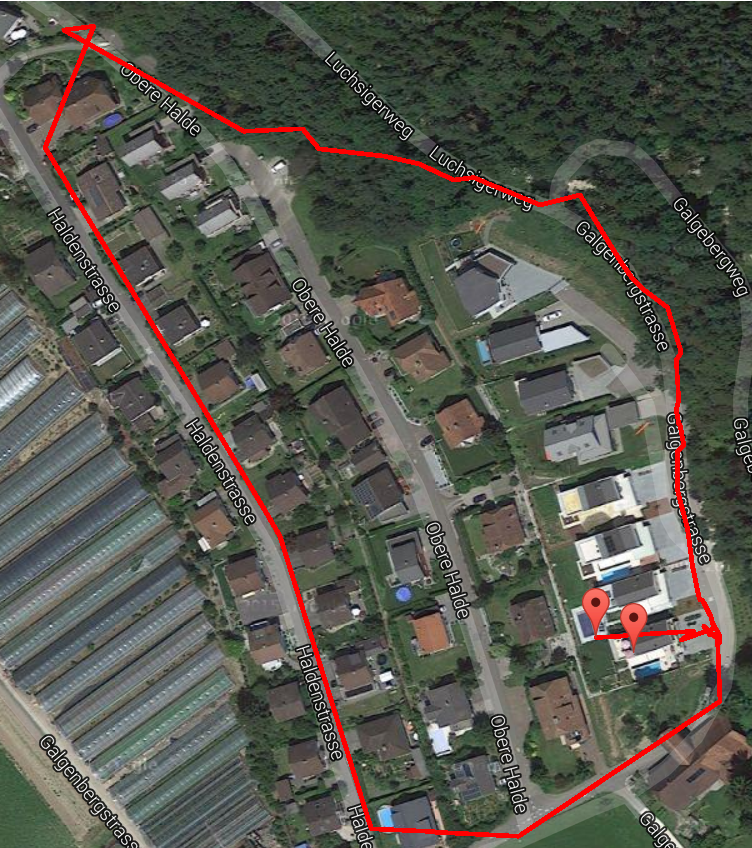

On 25.09.2016, 21:47:07 Wiggle (one of our test cats) lost his collar. He tried to squeeze through a hole in a chain-link fence and got stuck. The security buckle of the collar opened (correctly) and we recovered the collar the next day thanks to the accurate GPS position.

In this case the safety buckle worked correctly. The collar came to no harm and Wiggle is safe and sound.

In this case the safety buckle worked correctly. The collar came to no harm and Wiggle is safe and sound.

Test Statistics

Test Statistics

The first position was sent to the (new) prototype web portal on 8 July 2016 on 12:33.

Since then (status 22.09.2016, 14:45) a total of 968’438 messages were recorded from the petTracer receivers and collars. 87’652 were GPS positions sent from a total of 42 different collars.

“The test winner”, collar number 53 sent a total of 5’347 positions within approximately 38 days to our web portal, which corresponds to an average of 140 positions per day.

Of all the GPS positions recorded from collars which had already implemented quality validation filters (filters for accuracy):

- 10’323 GPS positions had the top grade

- 7’817 GPS positions were of average quality and

- 1’475 provided at least three valid measurements

Note: The remaining 68’037 GPS positions where transmitted without quality validation filters, as this feature was only implemented towards the end of the testing phase.

Stress Test

In March we informed you about our stress test. The aim was to test the robustness of the electronic components under the most adverse circumstances. The first test with the mounted flex-print was very successful. Even after several thousand twists the electronics were still fully functional.

Since the first test went well, we had decided to integrate further stress tests in the field test itself.

During the field test, we had an unpleasant surprise, after having analyzed some of the defective hardware. The prototype case used had a negative impact on the electronics over time. Instead of protecting delicate parts, it shifted pressure points onto the sensitive areas (including towards the GPS module) and injured them. However, we did managed to “save” most of the collars for the time being through expensive and time consuming repair work.

During the field test, we had an unpleasant surprise, after having analyzed some of the defective hardware. The prototype case used had a negative impact on the electronics over time. Instead of protecting delicate parts, it shifted pressure points onto the sensitive areas (including towards the GPS module) and injured them. However, we did managed to “save” most of the collars for the time being through expensive and time consuming repair work.

Instead of spending more time with this hardware, we decided on undertaking the final hardware iteration and optimization for the market product. For this we will now order the necessary tools and use the final case material which will be more robust and waterproof. The entire production for the next step is done in close cooperation with our (new and final) hardware manufacturer. So this is good news.

Kaddz in liquidation

Some time ago we received unpleasant news from the company “Kaddz”.¬† They have declared bankruptcy. Although being a direct competitor of us, we still regret this as we knew one of the founders personally. Moreover, it is always a shame when a startup or a company, in general,¬† goes bankrupt. Usually such people always put a lot of passion and commitment into their companies.

What we have learned from this is that we definitely made the correct decision. We made the decision to bring a valuable, workable product onto the market. This includes a very carefully planned long term test. The quality and reliability is and will remain the most important factor for a GPS cat collar.

Inquiries

Meanwhile inquiries for our petTracer GPS cat collar are increasing again but nevertheless we always try to respond in time.

We wish you all a good week.

Kind regards,

Alan & Claudio

News regarding prototype production

News regarding prototype production